A New View of Quality

Each of our chairs, sofas and loveseats are a masterpiece of comfort, beauty, and long lasting quality. Take a minute to look at what's inside our seating...

Hardwood Frame Construction

Hardwood Frame Construction

Kiln dried hardwood lumber is used for the foundation of each frame. All frames are cut precisely and assembled by hand using select 5/4''hardwoods, which are then joined by glue and double-dowels to strengthen and reinforce the frame. The 4 corners of the frame are reinforced with corner blocks which are glued, screwed, and stapled to the frame, a process that triples the strength and stability of the frame. All frames are sanded along the edges to create softer lines and eliminate hard edges that over time can be abrasive to upholstery material.

Eight-Way Hand Tied Support

Steel bands are stretched under strips of webbing and are double nailed to the frame. This is the foundation for the spring chamber which adds incredible strength and eliminates the possibility of any future sagging.Eight-way hand-tied double cone coil springs are securely nailed to the hardwood frame and offer the ultimate in firm support and long lasting comfort. Eight-way hand tying is an age-old construction technique...passed down through generations of craftsmen and women. It is an art which takes time and patience... but for exquisite comfort... there is NO substitute! We combine the best of traditional hand craftsmanship and modern technology to produce frames that are among the finest in the upholstery business

Hand Cutting and Sewing

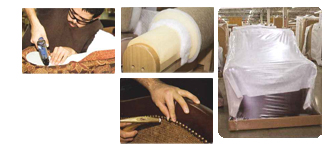

Fabric and leather patterns are measured and marked by hand to insure accuracy. Fabrics and leathers are individually cut by hand with great attention to detail and quality standards. Our cutting and sewing departments follow strict guidelines to assure the highest standards in fabric matching and high-end upholstery tailoring.

360 Degree Tailoring

Each frame is upholstered by an experienced craftsman with great attention to detail. Layers of cotton batting and pre-formed rubber are used throughout the frame for unseen form and luxurious comfort. Many frames are standard with accent nails which are meticulously applied one at a time by the hands of an experienced craftsman.

Each frame is upholstered by an experienced craftsman with great attention to detail. Layers of cotton batting and pre-formed rubber are used throughout the frame for unseen form and luxurious comfort. Many frames are standard with accent nails which are meticulously applied one at a time by the hands of an experienced craftsman.

Finishing Touches

Each piece of furniture is examined thoroughly for any imperfections and must meet the highest quality standards before being approved for shipment. After final inspection is complete, each item is placed on a heavy duty custom fitted cardboard tray, covered with a protective blanket, and shrink wrapped to insure safety during shipment.